Puddling Europe

In the first half of the nineteenth century, a new steel production process called ‘puddling’ found its way across the English Channel from Britain to continental Europe.

The process partly mechanized steel production. The puddling furnace allowed fuel to be separated from the iron by means of fire bricks, which meant that the iron was exposed to the heat, but not to the fuel. This process avoided the impurities that resulted from direct contact between the pig iron and coke or coal, allowing the production of purer and harder steel.

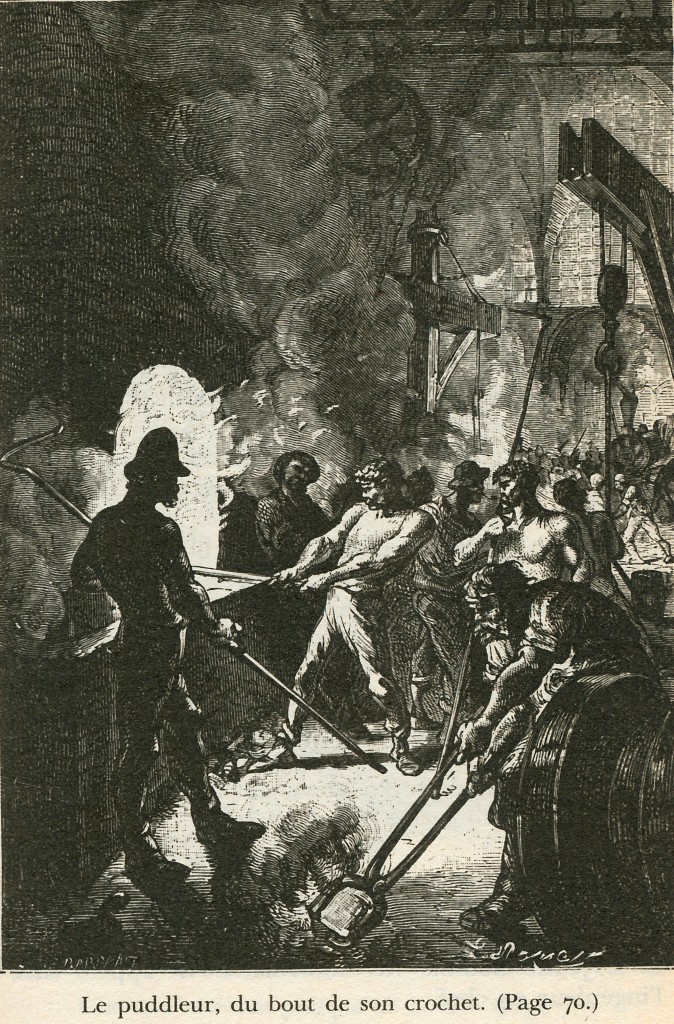

British puddlers first learned to stir the molten iron continuously with a paddle. Experienced workers were required in order to produce material of consistent quality. Thus, British puddlers were in high demand and well paid in continental Europe, initially in Belgium and the Rhineland, where they helped establish and improve steel production.

Entrepreneurs who migrated from Britain were the first to transfer the process to continental Europe. In 1817, Charles James and John Cockerill set up an iron foundry and a machine building factory at Seraing (in what would become Belgium in 1830). Here, they introduced the puddling process.

Like later technological innovations, the new process traveled freely, making Europe the center of the steel industry for more than 150 years.

How to cite this page

Wolfram Kaiser, 'Puddling Europe', Inventing Europe, http://www.inventingeurope.eu/governance/puddling-europe

Sources

- Halleux, Robert. Cockerill: deux siècles de technologie. Alleur-Liège: Ed. du Perron, 2002.

- Wengenroth, Ulrich. Enterprise and Technology. The German and British Steel Industries. Cambridge: Cambridge University Press, 1994.